If you’ve been searching for a full-colour branding method that works across different fabrics, handles fine detail, and feels great to wear — it’s time to get familiar with Powerprint. This modern garment decoration technique is making waves in the promotional clothing industry, and for good reason.

Whether you’re a business looking to create eye-catching staff uniforms, a club wanting a clean look for your next batch of caps, or an event organiser chasing cost-effective but high-quality branded merch, Powerprint could be exactly what you’re looking for.

In this blog, we’ll break down exactly what Powerprint is, how the process works, how it compares to other branding methods, and most importantly — when to use it.

What Is Powerprint?

Powerprint is a direct-to-film (DTF) heat transfer process. It allows you to apply vibrant, high-resolution, full-colour graphics to clothing and accessories, including hard-to-print items like hats, bags, and technical fabrics. The process involves printing your logo or design onto a special film, adding an adhesive powder, and then heat pressing the transfer onto your garment.

Unlike traditional screen printing or embroidery, Powerprint doesn’t rely on stitching or layered ink. Instead, it uses high-definition inks and adhesives that bond with the surface of the fabric to deliver a soft, flexible, and long-lasting finish.

Step-by-Step: How the Powerprint Process Works

When Should You Use Powerprint?

Powerprint is perfect for:

- Full-colour logos with gradients or photographic detail

- Short to medium runs, where screen printing might be cost-prohibitive

- Synthetic or technical fabrics like polyester or microfiber

- Caps, bucket hats, or bags that may not suit embroidery

- Fast turnarounds where setup time matters

However, it might not be ideal for high-friction areas or heavy industrial workwear where embroidery may outlast a printed surface.

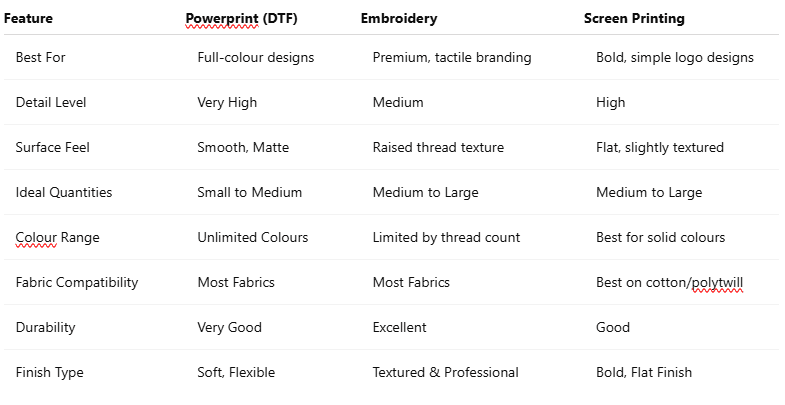

Comparing Powerprint, Embroidery, and Screen Printing

Here’s a clear comparison to help you choose the right method for your project:

Key Benefits of Powerprint Transfers

Full-Colour Capability: Unlike screen printing (which charges per colour), Powerprint allows multi-colour and photo-quality designs at no extra cost.

Great for Small Runs: Economical for small quantities where screen printing setup would be costly.

Smooth, Matte Finish: The result has a soft, flexible finish that feels less plasticky than vinyl transfers.

Works on Most Fabrics: Cotton, polycotton, polyester—Powerprint is very versatile.

Durability: High wash resistance (generally better than regular heat transfers).

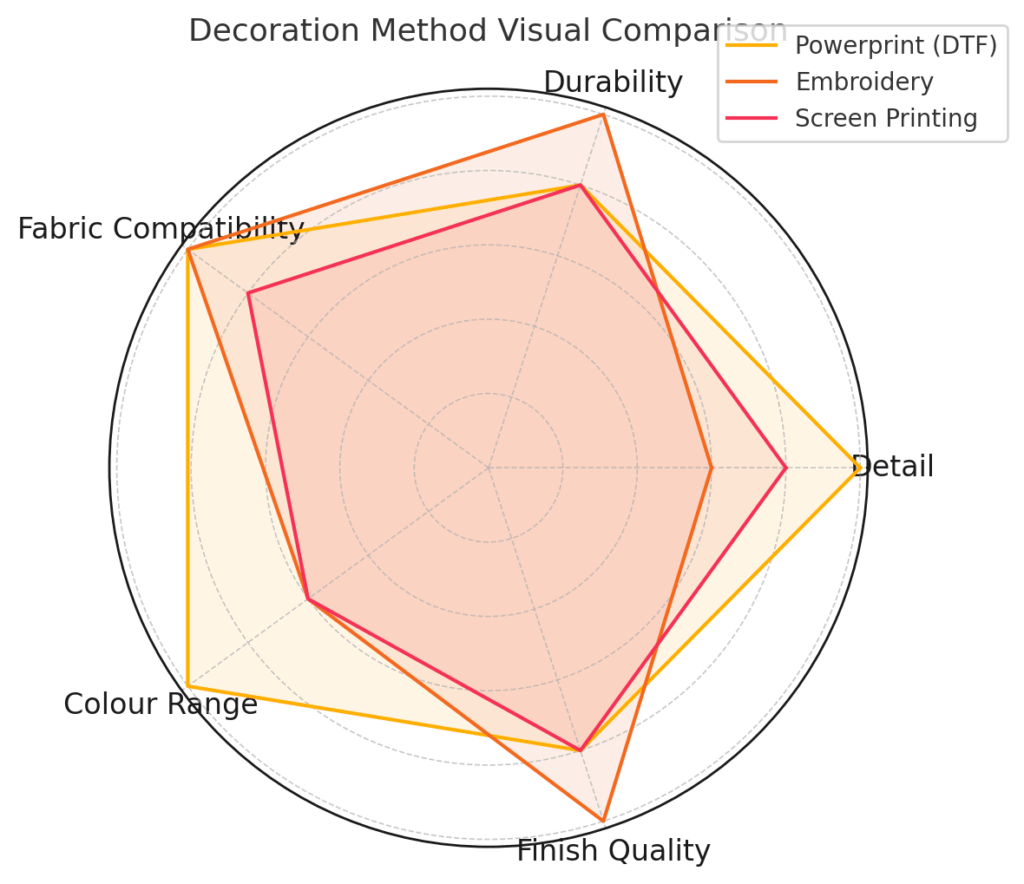

Visual Comparison: The Radar Chart

This chart highlights how Powerprint scores across five key features:

- Detail: Powerprint scores a 5 thanks to its ability to print ultra-fine, photographic-level designs.

- Durability: A solid 4, making it reliable for most day-to-day garments.

- Fabric Compatibility: Works on a wide range of materials — score of 5.

- Colour Range: Unlimited colours and gradients — score of 5.

- Finish Quality: Smooth, matte, and soft to wear — score of 4.

While embroidery remains the go-to for durability and a premium stitched look, Powerprint leads in flexibility, speed, and vibrant colour application.

Powerprint isn’t just a trendy new technique — it’s a powerful tool for businesses that want high-impact branding without sacrificing fabric compatibility or comfort. Whether you’re printing polos, t-shirts, bucket hats, or bags, Powerprint gives you creative freedom and professional results.

Still unsure if it’s the right fit for your job? Reach out to our team at Fast Clothing — we’ll help you choose the best method based on your logo, budget, and wear conditions.

Need help bringing your design to life? Contact us here or explore our custom branded apparel to get started today.