Embroidery

Embroidery is the traditional method of decorating fabrics with threads however we have an army of automatic machines rather than by hand.

Embroidery offers a clean and professional finish and can be used on a wide range of products including Apparel. The key to achieving a great embroidery job is in the digitising of your logo, and we spend the time to make sure that your logo looks the best it possibly can.

Our embroidery prices are based on a 10,000 stitch count. Don’t worry if you aren’t sure what this means. Just upload your logo and we will work it out for you and confirm the price in a quote.

If you are ordering less than 100 pieces there will be a one off set up fee of $75.00. For all orders over 100 pieces set up is FREE.

COLOUR MATCHING

Please note: It is highly recommended that PMS colours are provided to match your corporate colours as close as possible when decorating with embroidery or screen/pad/plastisol printing. Exact matches are not always possible. If PMS colours are not provided we cannot take responsibility for incorrect colours, however we will always do our best to match as close as possible.

Power Print

Power Print can reproduce logos so perfectly they look like they are part of the garment.

Using a 4 colour digital process a sticker is printed. It is then heat pressed onto the garment allowing the ink to transfer to the material.

There are no outlines or borders, just vibrant colour.

What are the benefits of using Power Print?

- This process can be used for 70% of apparel branding

- Perfect for full colour images and high detail

- Equivalent to screen printing in terms of durability

- Saves time and money with very simple, cost effective pricing structure

What are the Limitations of Power Print?

- Cannot reproduce exact PMS colours

- Cannot reproduce exact match for flouros or metallics

Screen Printing

Screen Printing is the traditional form of printing in which ink is applied directly to the surface using a screen. When printing more than 1 colour, multiple screens must be used and the process repeated for each colour so pricing for screen printing is based on how many colours are printed.

Screen printing is generally used for 1 or 2 colour logos and can be applied to almost any product. It is the perfect process for large quantities.

Benefits

- Large print areas are possible on flat products.

- Close PMS matches are possible on white or light-coloured products.

- Most screen print inks dry quickly and can be shipped immediately after printing.

- Fluorescent, metallic gold and silver inks are available on select textile products.

- Many products can print with tight multi-colour registration, with some products able to be printed using up to five colours.

Limitations

- Close PMS matches are more difficult on darker products and will only be approximate. In some instances, a white base will create a better print.

- Unable to print variable data.

- Each colour requires its own setup charge.

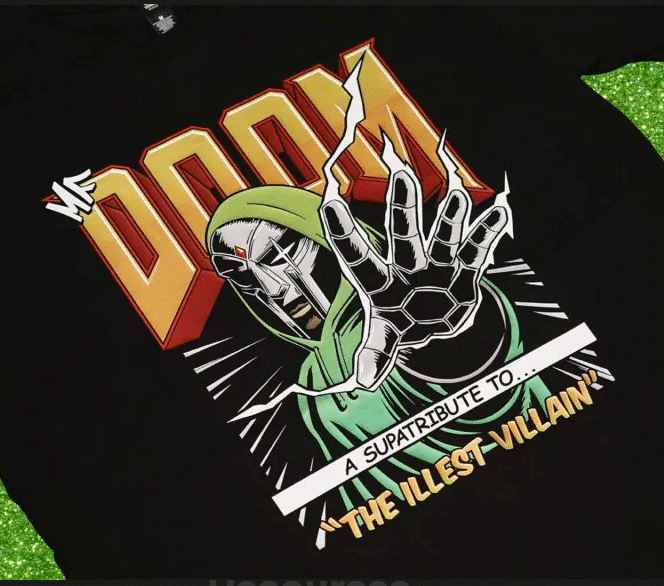

Supacolour

Supacolour is the latest technology in digital reproduction of logos. It can reproduce logos perfectly without a need to compromise.

What are the benefits of using Supacolour?

- Unlimited colours and high vibrancy

- Ultra-high detail (finest of text, perfect colour gradients)

- Allows free floating text without any weeding required, hence the low cost

- Ultra-high resolution photo reproduction achievable

- High stretchability and versatility in terms of fabrics and where it can be applied

- Robust! Can be applied across seams and on coarse fabrics.

- 100 washes, will outlive the product and won’t peel, crack or fade.

- Using the highest quality, eco-friendly inks and no vinyl as well

- Saves time and money with very simple, cost effective pricing structure

Digital Full Colour Heat Transfer

Similar to powerprint, a digital heat transfer is a printed digital sticker which is applied via a heatpress machine to a garment. The process is a 4 colour print process using colours closely match to PMS colours.

However, unlike powerprint, the sticker needs to be ‘weeded’ before application. Weeding is the process of removing the excess parts of the sticker that are not part of the design. This can be time consuming.

Digital Full Colour Heat Transfers are durable and suitable for all garments. They are especially useful where high quality photographic quality logos/graphics are needed. It is also perfect for reproducing a range of specialty colours including metallic colours.